Office USA: 706-658-1122 | Tech Support: 706-362-4813

Office Bulgaria: +359 431 64477

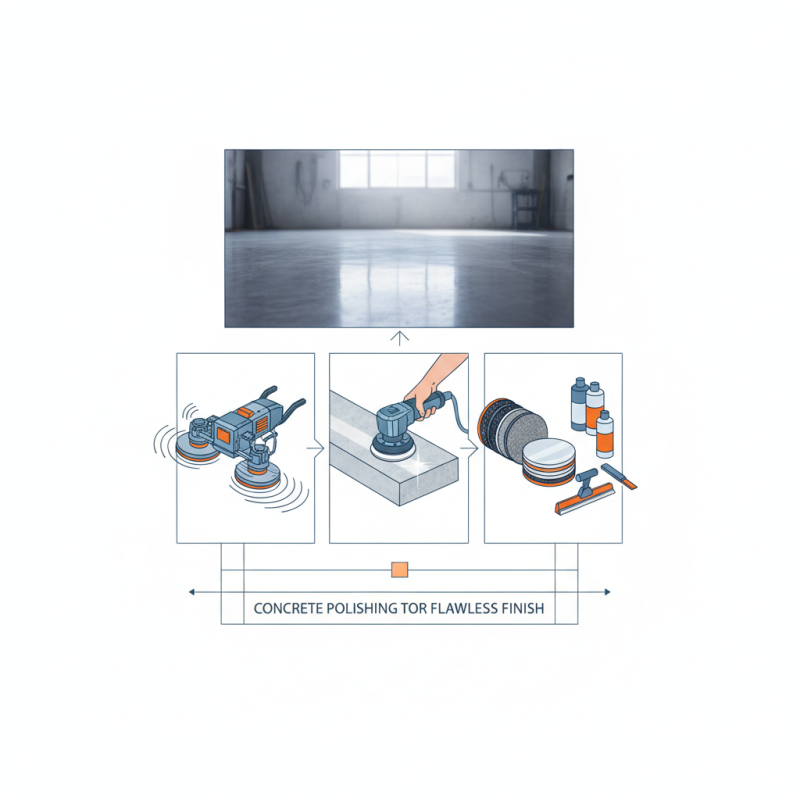

What Are the Best Concrete Polishing Tools for Perfect Finish?

Concrete polishing tools are vital for achieving a flawless finish on concrete surfaces. Selecting the right tools can make a significant difference in the quality of your work. This guide explores some of the best tools available, ensuring you have the right equipment for the job.

A variety of concrete polishing tools exist, each designed for specific tasks. From grinders to polishers, choosing improperly can lead to less-than-ideal results. Some might struggle with durability, while others may not provide the desired shine. Understanding these tools is crucial for both professionals and DIY enthusiasts.

Getting the perfect finish requires skill and the right tools. However, even the best polishers can falter if used incorrectly. It's essential to learn from each project and refine your approach. Polishing concrete is an art, and perfection is often a journey filled with trial and error.

Types of Concrete Polishing Tools and Their Functions

Concrete polishing tools come in various types, each tailored for specific tasks. A popular choice is the floor grinder, essential for leveling and smoothing surfaces. These machines often operate on multiple heads. This allows for uniform polishing and efficient material removal. Industry data suggests that using a dual-head grinder can reduce polishing time by up to 30%.

Another crucial tool is the concrete polisher, which provides the final gloss finish. It uses diamond polishing pads in various grits. Data indicates that starting with a coarse pad, then moving to finer ones, achieves the best results. Many professionals suggest that skipping grits can lead to an uneven finish. It’s important to keep a close eye on the process.

Vacuum systems are just as vital, controlling dust during polishing. A well-functioning vacuum removes particles and enhances visibility. Some job sites report decreased productivity due to dust interruptions. This emphasizes the need for a robust vacuum setup. Optimal tool choice can significantly impact the final outcome. However, even with the best tools, imperfections might arise. An attentive operator can spot and refine these areas for best results.

What Are the Best Concrete Polishing Tools for Perfect Finish?

| Tool Type | Function | Material Compatibility | Optimal Use Case |

|---|---|---|---|

| Concrete Grinder | Removes excess material, smoothens surface | Concrete | Surface preparation prior to polishing |

| Polishing Pads | Provides a fine finish to concrete surfaces | Concrete, Terrazzo | Final polishing stage for shine |

| Floor Buffer | Enhances shine and removes surface imperfections | Concrete, Marble | Routine maintenance and cleaning |

| Vacuum System | Removes dust and debris during polishing | All types | Maintaining cleanliness during work |

| Edge Grinder | Cleans and polishes edges and corners | Concrete, Epoxy | Detail work on edges and tight spaces |

Essential Features to Look for in Polishing Tools

When selecting concrete polishing tools, certain features are crucial for achieving a perfect finish. A powerful motor is essential. It determines the tool's efficiency and effectiveness. A motor with at least 3 horsepower can handle the demands of tough concrete surfaces. Additionally, variable speed controls allow for adjustments based on specific polishing needs. Many professionals recommend a speed range of 500 to 3,000 RPM for optimal results.

Weight is another important factor. Heavier tools tend to provide better pressure during polishing. However, this can lead to user fatigue. Finding a balance between weight and maneuverability is vital. A tool that weighs around 100 pounds, for instance, offers enough pressure without feeling cumbersome for extended use. Remember, the right tool should feel comfortable in your hands while still being effective.

Dust collection systems are often overlooked. During polishing, concrete produces significant dust. A good dust collection system keeps the workspace clean and reduces respiratory risks. Some reports suggest up to 70% of workers face health issues due to poor dust management. Investing in a tool with an efficient dust system can pay off in both long-term health and productivity.

Step-by-Step Guide to Using Concrete Polishing Tools

When using concrete polishing tools, achieving a perfect finish requires attention to detail. Begin with a thorough surface preparation. The concrete must be clean and free of debris. Use a floor scrubber to remove any contaminants. According to industry reports, more than 30% of polishing failures stem from inadequate surface preparation.

Once the surface is ready, choose the right diamonds for polishing. Start with coarse grits and gradually move to finer ones. It's essential to keep the pad moist. Dry polishing can lead to scratches and uneven surfaces. Many professionals recommend using a wet system to avoid dust. Be aware that skipping grits may result in a subpar finish.

Polishing can be an iterative process. Monitor the surface closely during each phase. Sometimes, areas may require more work than anticipated. It’s vital to remain patient and adjust techniques as needed. Even experienced contractors face challenges. A perfect polish often demands multiple passes and adjustments. Regularly inspect your progress and be prepared to refine your approach.

Maintenance Tips for Prolonging the Life of Polishing Tools

Maintaining concrete polishing tools is crucial for achieving a perfect finish. Regular maintenance extends the life of your tools and ensures optimal performance. Start by cleaning tools after each use. Remove any dust and debris that may have accumulated. This prevents particles from scratching surfaces during the next polishing session.

Check the pads frequently. They wear down with use, impacting the quality of the finish. Replace pads when they become uneven or discolored. Storing tools properly is vital as well. Avoid leaving them exposed to moisture, which can lead to rust or degradation. A dry, climate-controlled area is ideal.

Do not overlook the importance of regular inspections. Look for any signs of damage, such as cracks or bent parts. Even minor defects can lead to significant issues later on. Consider keeping a maintenance log to track the condition of your tools over time. With careful attention and proper care, your concrete polishing tools can deliver outstanding results for years to come.

Recommended Brands for Quality Concrete Polishing Tools

When choosing concrete polishing tools, quality is paramount. There are various brands known for producing reliable equipment. These tools range from handheld grinders to large floor machines. Each type serves a unique purpose in the polishing process. A sturdy, durable tool can make a difference in achieving a perfect finish.

Many professionals often overlook the importance of pads. The right pad can enhance the polishing experience. Some may find it challenging to select the appropriate grit size for their project. A common mistake is assuming all pads work the same. In reality, different surfaces require specific pads for the best outcome.

Maintenance of tools is another factor to consider. Clean and cared-for tools function better and last longer. Neglecting them can lead to subpar finishes and increased costs. Investing in quality tools is essential. However, always be ready to reflect on their performance and adjust as needed. The journey to a flawless concrete surface is rewarding, but it demands attention to detail and constant learning.

Related Posts

-

How to Choose the Right Concrete Grinding Equipment for Your Project Needs

-

Top Concrete Grinding Equipment for 2026 What Should You Know?

-

Unlocking the Power: Benefits of Using a Concrete Hand Grinder for Your DIY Projects

-

Top Tips to Identify Quality Suppliers of Best Concrete Hand Tools with a Comprehensive Checklist

-

Mastering the Art of Selecting the Best Grinding Tools for Your Industrial Needs

-

Ultimate Guide to Using a Concrete Hand Grinder for Flawless Finishing