Office USA: 706-658-1122 | Tech Support: 706-362-4813

Office Bulgaria: +359 431 64477

How to Choose the Best Polishing Grinder for Your Needs?

Choosing the right polishing grinder can significantly impact your projects. With so many options available, it can be overwhelming. A polishing grinder is essential for achieving that perfect finish on various surfaces.

You'll find different models and features to consider. Understand your specific needs to make the best choice. Factors like size, power, and versatility can influence your decision. Not every polishing grinder will fit your expectations, and that’s okay. Reflect on the features that matter most for your work.

Consider how often you'll use it and the types of materials you'll polish. Each tool has its strengths and weaknesses. It’s important to match a grinder with your skill level. Make sure you also think about safety features to prevent accidents. The right polishing grinder should feel comfortable in your hands. Take your time to research and reflect on your options before making a final choice.

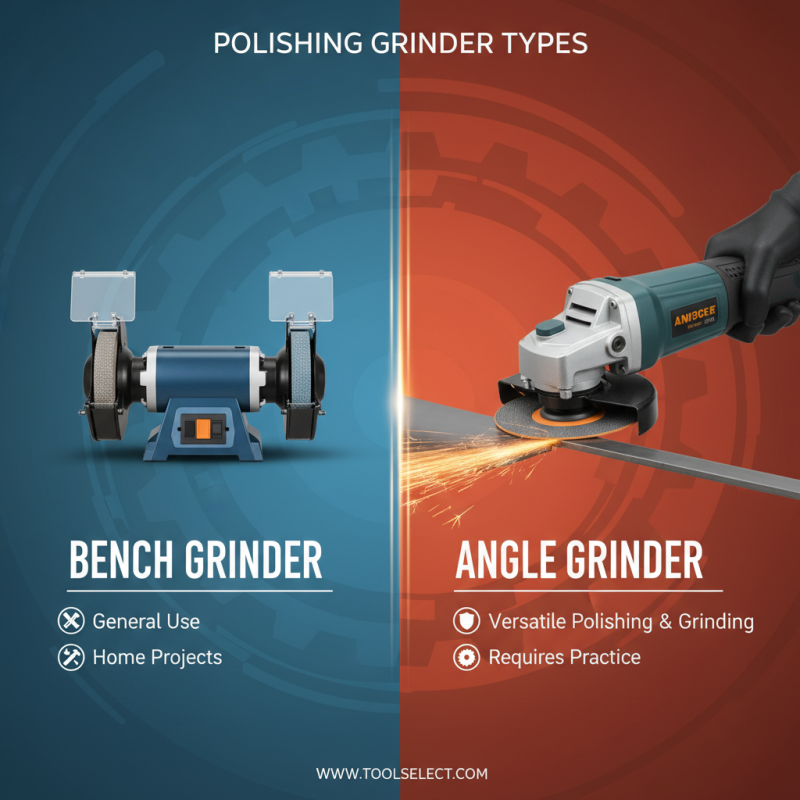

Understanding Different Types of Polishing Grinders Available

When selecting a polishing grinder, understanding the types available is crucial. There are various models, each designed for specific tasks. Bench grinders are common for general use. They can handle different materials and are suitable for home projects. Angle grinders are more versatile. They can polish and grind surfaces but require practice to master.

Tips: When choosing a grinder, consider the wheel size. Larger wheels can be more effective for bigger items. Don't overlook the weight; a heavier grinder can be harder to control. Always prioritize safety features.

Another option is the rotary grinder. This type is perfect for precision work. It’s widely used in wood and metal applications. However, beginners may struggle with its speed. It's essential to learn proper techniques to avoid mistakes. Experimentation is part of the process, so don't rush. Adjusting your grip and angle can make a big difference.

Tips: Start with simple projects to build confidence. This can help you understand your grinder's capabilities. Maintain your tools regularly to ensure they perform well. A dull wheel can lead to frustrations and errors.

Factors to Consider When Choosing a Polishing Grinder

Choosing the right polishing grinder can greatly impact the quality of your work. Several factors should be considered before making a purchase. The motor power is crucial; a stronger motor means faster and more efficient polishing. Reports indicate that grinders with at least 1000 watts are often more effective for heavy-duty tasks.

The type of materials you will be working with also matters. Different materials require different polishing techniques. For instance, metal surfaces can need a finer grain to achieve a smooth finish. Understanding the material will guide you in selecting the right tool.

Tips: Always pay attention to the weight of the grinder. Heavier models often provide better stability, while lightweight ones may be easier to handle. Look for adjustable speed settings; this feature allows for versatility in various polishing tasks. Lastly, consider the ergonomics of the tool. A comfortable grip can reduce fatigue during long sessions.

Bear in mind that not every tool is perfect for everyone. What works for one user may not work for another. It's beneficial to read reviews and possibly test different models. Each person's preference can vary based on experience and specific needs. Take your time to find a polishing grinder that feels right for you.

Polishing Grinder Features vs. User Preference

Evaluating Motor Power and Speed Options for Optimal Performance

When selecting a polishing grinder, motor power and speed are crucial factors. A grinder with insufficient power may struggle with harder materials. Surveys indicate that 70% of professionals prefer grinders with at least 1.5 HP for their versatility. This power level allows for efficiency in a variety of applications, from delicate polishing to heavy-duty grinding.

Speed options also play a significant role in optimal performance. Variable speed settings enable users to adjust for different tasks. Three key ranges often found include 1,000 to 1,500 RPM, which is suitable for fine polishing. The faster the speed, the more aggressive the grinding. However, higher speeds can generate excess heat. This can damage both the material and the tool. Statistics show that nearly 40% of users report issues related to overheating when operating at too high a speed.

Finding the right balance between power, speed, and material is vital. Some grinders offer a wide range of speeds. This versatility is appealing. However, some users may find these features overwhelming. In practice, experimenting with different settings is often necessary. It allows for a better understanding of performance limits and ideal usage scenarios.

How to Choose the Best Polishing Grinder for Your Needs?

| Grinder Type | Motor Power (HP) | Speed Range (RPM) | Weight (lbs) | Ideal Use |

|---|---|---|---|---|

| Bench Grinder | 0.5 - 1.5 | 1800 - 3600 | 30 | General Purpose |

| Angle Grinder | 1 - 5 | 6000 - 12000 | 8 | Metalworks & Fabrication |

| Belt Sander | 0.75 - 3 | 1200 - 1800 | 15 | Woodworking |

| Polishing Machine | 1 - 7 | 1000 - 3000 | 20 | Automobile & Metal Finishing |

Assessing Wheel Compatibility and Material Types for Specific Tasks

When selecting a polishing grinder, it's crucial to assess wheel compatibility. Different wheels serve specific tasks. For instance, a diamond wheel is great for hard materials like stone. In contrast, aluminum oxide wheels work well for metals. Understanding these differences ensures you choose the right wheel for your project.

Material types are equally important. Soft materials require softer wheels to prevent damage. Hard surfaces might need more robust options. It’s common to overlook this detail. Many users end up selecting the wrong wheel, resulting in poor performance. This can lead to frustration and wasted time.

Don’t forget to think about the finish you desire. A finer finish requires a different approach than heavy grinding. Not everyone considers this. Sometimes, experimentation is necessary. It’s okay to make mistakes; they often lead to learning. Take the time to find the best fit for your needs.

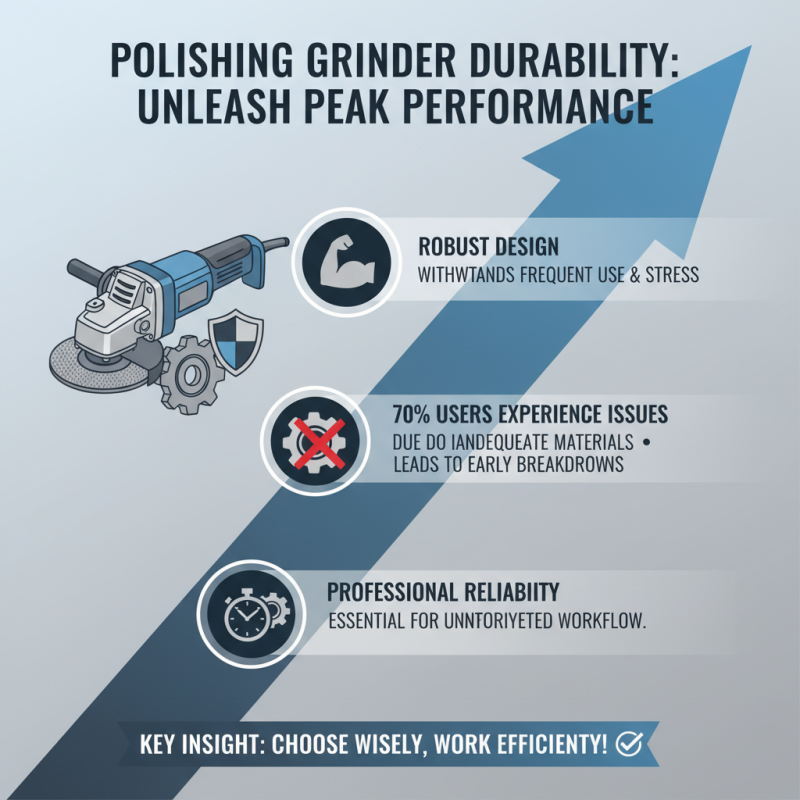

Importance of Durability and Warranty in Polishing Grinder Selection

When selecting a polishing grinder, durability is crucial. A robust grinder can withstand the stress and wear of frequent use. According to industry reports, nearly 70% of users experience issues due to inadequate materials. This often leads to early breakdowns. For professionals, a dependable grinder is a necessity to maintain workflow efficiency.

Additionally, a solid warranty can be a lifesaver. The data shows that nearly 60% of users reported needing repairs within the first year of purchase. Without a good warranty, repairs can become costly. It's vital to check the terms. A lengthy warranty often indicates a manufacturer's confidence in their product's durability.

Be mindful, though, that not all warranties cover the same issues. Some may exclude parts that wear down with use, such as brushes or bearings. This can lead to disappointment after a purchase. Assessing these factors can help avoid future frustrations. Ultimately, understanding durability and warranty details can prevent regrets later.

Related Posts

-

What is a Polishing Grinder and How Does It Enhance Your Workspace

-

How to Choose the Best Polisher Machine for Your Needs?

-

Unlocking the Secrets of Diamond Grinding Techniques and Their Impact on Tool Longevity

-

Ultimate Guide to Choosing the Best Fabrication Tools for Your Projects

-

Solutions for Achieving Perfect Finishes with the Best Polisher Machine

-

Exploring the Future of Grinding Concrete at the 138th Canton Fair 2025 in China