Office USA: 706-658-1122 | Tech Support: 706-362-4813

Office Bulgaria: +359 431 64477

How to Choose the Best Concrete Finishing Machines in 2026?

The demand for concrete finishing machines is expected to rise significantly by 2026. Market research indicates a projected growth rate of approximately 6% annually. This growth can be attributed to increasing urban construction and infrastructure projects worldwide.

Choosing the right concrete finishing machines is crucial for efficiency and quality. A poorly selected machine can lead to uneven surfaces and increased labor costs. High-quality machines enhance not only the finishing process but also the overall durability of the concrete. For example, power trowels and concrete grinders show varied results in surface smoothness and finishing time.

Investing in the best equipment is essential for contractors. The right choices can improve productivity and reduce waste. Higher initial costs could mean better long-term performance. However, some companies still overlook maintenance needs, leading to costly repairs. Future success hinges on marrying quality with informed decision-making.

Understanding the Types of Concrete Finishing Machines Available

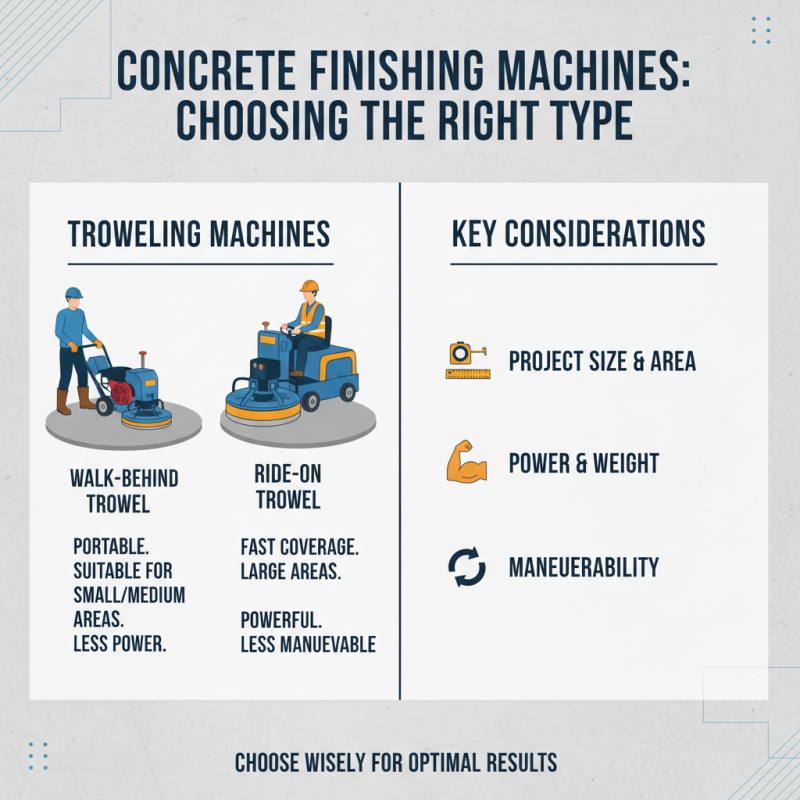

When choosing concrete finishing machines, it’s important to understand the types available. There are several machines designed for specific tasks. Troweling machines are common for achieving a smooth surface. They come in both walk-behind and ride-on models. The size and weight of these machines can vary widely. Smaller models are portable but may lack power. Larger models can finish big areas quickly but may be harder to maneuver in tight spaces.

Another option is the concrete screed, ideal for leveling before finishing. These machines can vibrate to help settle the concrete mix. A good screed can make a noticeable difference in the final look. Some designs allow for adjustable lengths. This can be helpful for projects of various sizes.

Consider the power source as well. Electric models are quieter and may work better indoors. Gas-powered machines deliver more power but can be noisy. Evaluate the nature of your project carefully. Different machines can affect the overall finish and efficiency of your work. Make sure to research and reflect on their differences before making a choice.

Evaluating Key Features and Specifications for Concrete Finishers

Choosing the right concrete finishing machine in 2026 can be challenging. Key features matter greatly. Begin with the engine power. A strong engine ensures efficient operation. This can save you time and energy on the job site. Consider machine weight too. A heavier machine provides stability, but can be harder to maneuver.

Look at the troweling width. Wider trowels cover more area but may miss tight corners. Pay attention to blade quality. Durable blades can reduce replacement costs over time. Also, inspect the controls. Intuitive controls can enhance productivity. Complex systems can lead to mistakes.

Ergonomics are crucial yet often overlooked. A comfortable grip reduces fatigue during long hours of work. Check user reviews. They often reveal insights about real-world performance. Finally, evaluate the machine's maintenance needs. High-maintenance models can become a burden. Reflecting on these aspects will lead you to the right choice.

Concrete Finishing Machines Comparison (2026)

Assessing Budget Constraints and Cost-Effectiveness of Machines

When selecting concrete finishing machines in 2026, budget constraints play a critical role. It's essential to assess your overall costs. What is your financial limit? Look beyond the initial purchase price. Maintenance and repair costs can significantly impact your budget over time. Consider machines with lower operating costs. They may save you money in the long run.

Evaluating cost-effectiveness is not just about upfront expenses. Think about the long-term value. Will this machine improve productivity? How often will it be in use? Often, cheaper options can lead to higher costs down the road. A high-quality machine may require more investment upfront but could yield better results. A critical reflection on your choices can help in making informed decisions.

Moreover, don't forget to factor in training costs. Some machines are more complicated to use. Are your team members equipped to handle these? Poor training can lead to costly errors. It's worthwhile to invest time into choosing the right equipment. Balancing your budget with quality and effectiveness is indeed challenging but necessary.

Researching User Reviews and Brand Reputation in the Market

When choosing concrete finishing machines, user reviews become invaluable. They provide insights into real-world performance. Users often share specific experiences, highlighting strengths and weaknesses. For instance, a machine that glides smoothly may have great user feedback. However, some reviews may mention durability issues. It's crucial to read a variety of opinions.

Brand reputation also plays a key role. A well-known name often indicates quality. Yet, popularity does not guarantee satisfaction. Some brands might have a stellar image but fail to deliver on performance. Pay attention to the longevity of their products in the market. Is the brand known for consistent improvements? Investigate any recalls or complaints. A trusted brand may still have shortcomings.

It's essential to filter through the noise. Look for detailed reviews that explain user sentiments. Simple ratings do not always tell the full story. Some users might find success with machines deemed less favorable by others. Personal needs and project specifics will greatly influence your choice. Don't shy away from machines that resonate well with your planned applications. Balancing brand reputation with honest user feedback will guide you toward the best decision.

How to Choose the Best Concrete Finishing Machines in 2026?

| Feature | Criteria | Rating (out of 5) | Comments |

|---|---|---|---|

| Power Source | Electric vs. Gas | 4.5 | Electric models are quieter and more environmentally friendly. |

| Weight | Light vs. Heavy | 3.8 | Heavier machines offer more stability but can be cumbersome. |

| Maneuverability | Ease of movement | 4.0 | Compact designs make it easier to navigate tight spaces. |

| Durability | Material quality | 4.3 | High-quality materials can withstand harsh conditions. |

| Price | Budget vs. Premium | 4.1 | Investing in premium models often yields better performance. |

| User Reviews | Feedback from professionals | 4.6 | Positive reviews highlight reliability and efficiency. |

Considering Maintenance and Support for Long-Term Use of Equipment

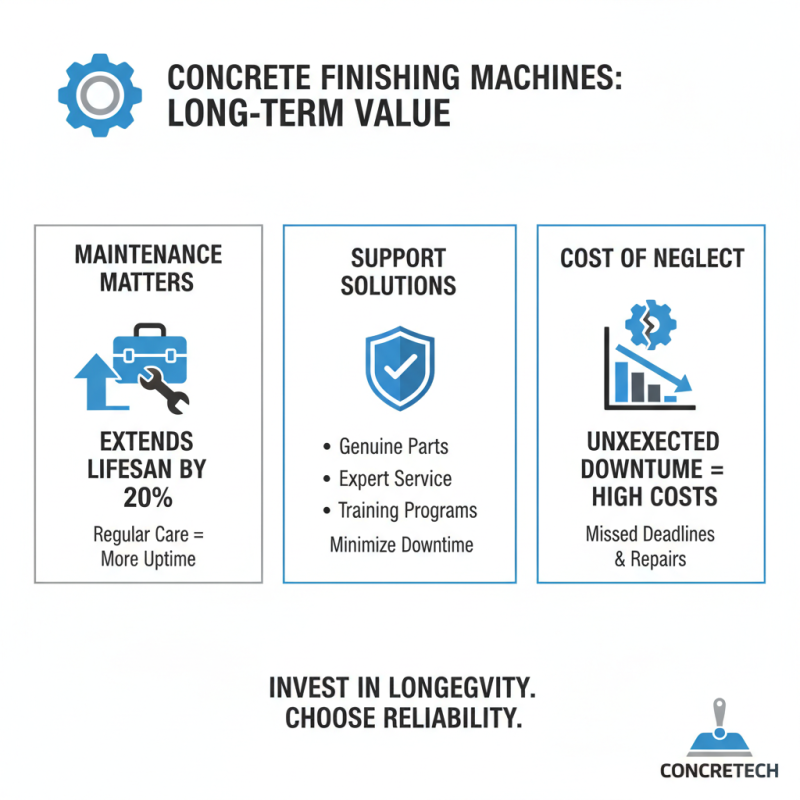

When choosing concrete finishing machines for long-term use, maintenance and support are crucial considerations. Regular maintenance can extend the lifespan of these machines significantly. According to industry reports, a well-maintained concrete finishing machine can last up to 20% longer than one that isn’t. Failing to adhere to maintenance schedules often leads to unexpected downtime, which can be costly.

Equipment support is equally important. Timely access to spare parts and technical assistance can make or break your operations. Studies suggest that businesses that have reliable support services see a reduction in repair times by up to 30%. However, not all manufacturers provide this level of service. It is essential to investigate the availability of support for your chosen equipment to avoid future frustrations.

Investing in training for operators also pays off. Skilled operators can perform routine checks and minor repairs, reducing reliance on external technicians. Still, some companies underestimate this aspect. A lack of operator training may lead to misuse and increased wear and tear on equipment. Therefore, consider the comprehensive support ecosystem that includes maintenance strategies, technical assistance, and operator training when selecting a concrete finishing machine.

Related Posts

-

What is a Polishing Grinder and How Does It Enhance Your Workspace

-

How to Choose the Right Concrete Grinding Equipment for Your Project Needs

-

Top Concrete Grinding Equipment for 2026 What Should You Know?

-

Top 10 Hand Grinders to Elevate Your Coffee Experience in 2025

-

Unlocking the Secrets of Diamond Grinding Techniques and Their Impact on Tool Longevity

-

Ultimate Checklist for Selecting the Best Floor Grinding Machines for Global Buyers