Office USA: 706-658-1122 | Tech Support: 706-362-4813

Office Bulgaria: +359 431 64477

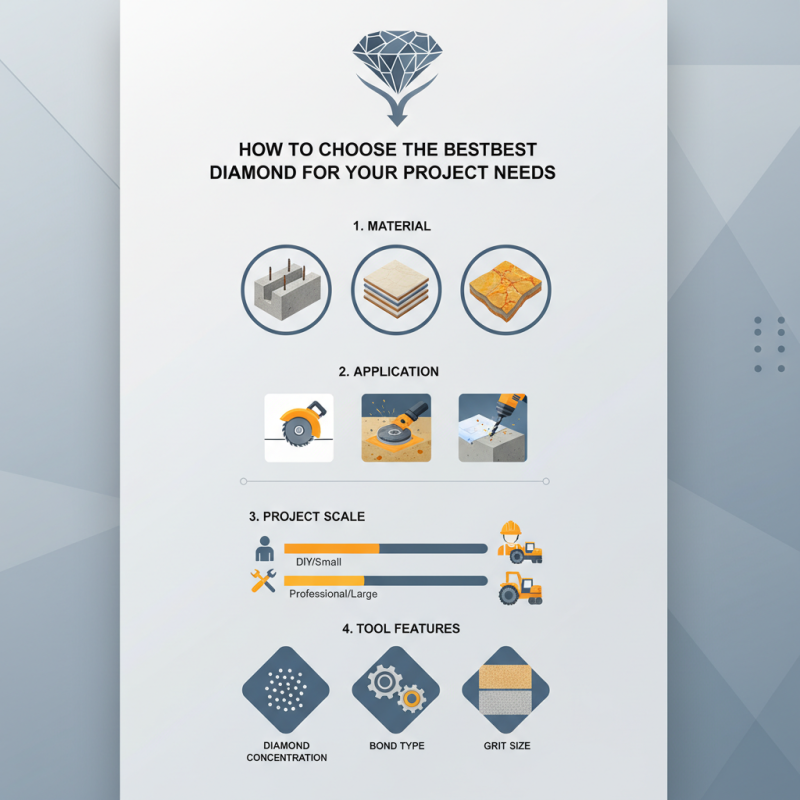

How to Choose the Best Diamond Tools for Your Project Needs

Choosing the right diamond tools for your project is essential for ensuring optimal performance and achieving the best results. Diamond tools are widely recognized for their durability and effectiveness in cutting, grinding, and drilling through a variety of materials, making them indispensable in both professional and DIY environments. With the market offering a vast array of options, understanding the specific requirements of your project becomes crucial in making an informed decision.

When selecting diamond tools, it's important to consider factors such as the material you will be working with, the type of work (whether it's cutting, grinding, or polishing), and the scale of your project. Different diamond tools are engineered for distinct applications; therefore, knowing the right tool for the job can save time, increase efficiency, and enhance the quality of your work. As you navigate through the selection process, paying close attention to features such as diamond concentration, bond type, and grit size will empower you to choose the best diamond tools tailored to your individual project needs.

Understanding Diamond Tools and Their Applications

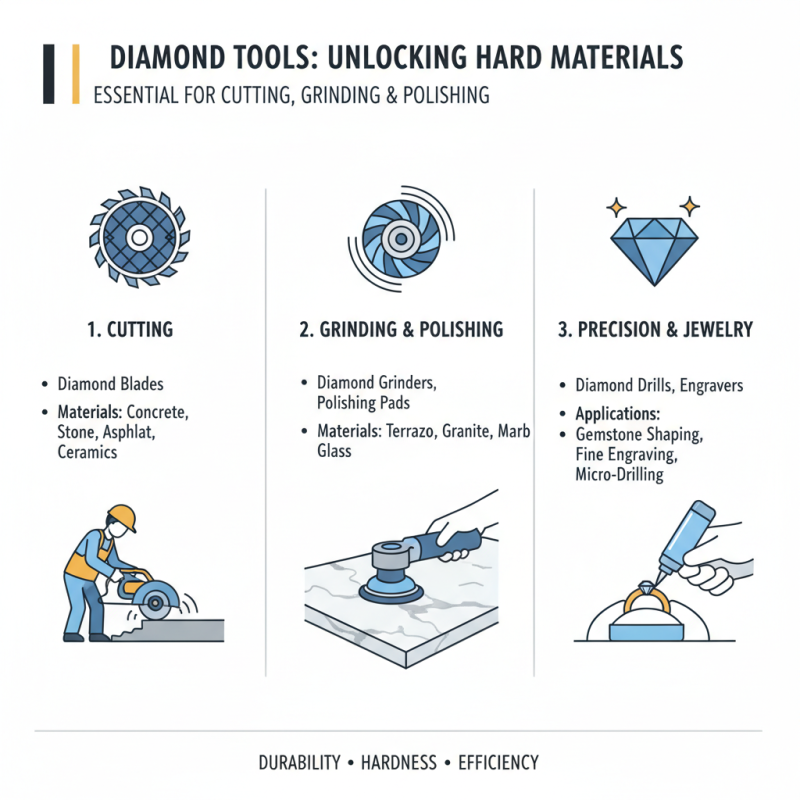

Diamond tools are essential in a variety of applications due to their exceptional hardness and durability. These tools are commonly used in industries such as construction, manufacturing, and even jewelry making. Understanding the specific types of diamond tools available can greatly enhance the efficiency of any project. For instance, diamond blades are primarily used for cutting hard materials like concrete, while diamond grinders are perfect for smoothing and polishing surfaces. Each tool serves a unique purpose and is designed to handle distinct materials and tasks, which makes understanding their applications critical for optimal performance.

Choosing the right diamond tool involves evaluating the material you'll be working with and the specific requirements of your project. For example, if you're cutting through granite or porcelain, a wet diamond blade will help minimize dust and keep the material cool. On the other hand, if precision is key in your work, a diamond-coated bit may be the best choice for drilling or engraving. Assessing factors such as the intensity of use, tool longevity, and cost-effectiveness will further guide your decision-making process, ensuring that you select the most suitable diamond tool for your specific project needs.

Types of Diamond Tools Available for Various Projects

When selecting diamond tools for various projects, it’s crucial to understand the different types available, each designed for specific applications. According to a report from the Grand View Research, the global diamond tools market was valued at approximately $4.33 billion in 2020 and is projected to grow by 5.2% annually through 2028. This growth is a reflection of the increasing demand for efficient and precise cutting and drilling tools across various industries.

Common types of diamond tools include diamond blades, core bits, and grinding wheels. For instance, diamond blades are primarily used for cutting hard materials such as concrete, asphalt, and stone, while diamond core bits are essential for drilling precise holes in masonry or concrete. The choice of tool often depends on the material being worked on and the desired finish; rough cuts and fast material removal may require different specifications compared to fine finishes. Industry-specific reports indicate that using the appropriate diamond tools can significantly increase productivity, with professionals noting up to a 30% improvement in cutting efficiency when using the right tool for the job. Understanding these distinctions is key to ensuring optimal results for your project.

Types of Diamond Tools and Their Applications

Factors to Consider When Choosing Diamond Tools

When selecting diamond tools for your project, several critical factors should be taken into account to ensure optimal performance and efficiency. One of the primary considerations is the type of material you will be working with. According to a report by Allied Market Research, the global diamond tools market is projected to reach $6.36 billion by 2026, driven by increased demand across industries such as construction, mining, and manufacturing. Each material requires specific diamond tool characteristics, such as grit size and bond type, to achieve desired cutting or grinding results.

Another essential factor is the tool's application and usage frequency. For instance, a continuous rim diamond blade works effectively for cutting tiles and ceramics, while segmented blades are better suited for masonry and concrete tasks. Research from the International Journal of Advanced Manufacturing Technology emphasizes that selecting the right tool can enhance productivity by up to 30%. Additionally, understanding the expected lifespan and durability of the diamond tool is crucial, as higher-quality tools may have a higher upfront cost but offer better performance and longer service life, ultimately providing greater value for your investment.

How to Choose the Best Diamond Tools for Your Project Needs

| Criteria | Description | Example Tools |

|---|---|---|

| Type of Material | Consider the materials you will be cutting or grinding. | Diamond blades for concrete, diamond cup wheels for stone. |

| Tool Compatibility | Ensure the diamond tool is compatible with your machinery. | Angle grinders, saws, or routers. |

| Grit Size | Choose the right grit size for your project needs. | Coarse for rapid removal, fine for finishing. |

| Tool Life | Look for tools with longer durability for cost-effectiveness. | High-quality diamond blades with extended life. |

| Safety Features | Consider tools that have integrated safety features. | Blade guards, kickback protection. |

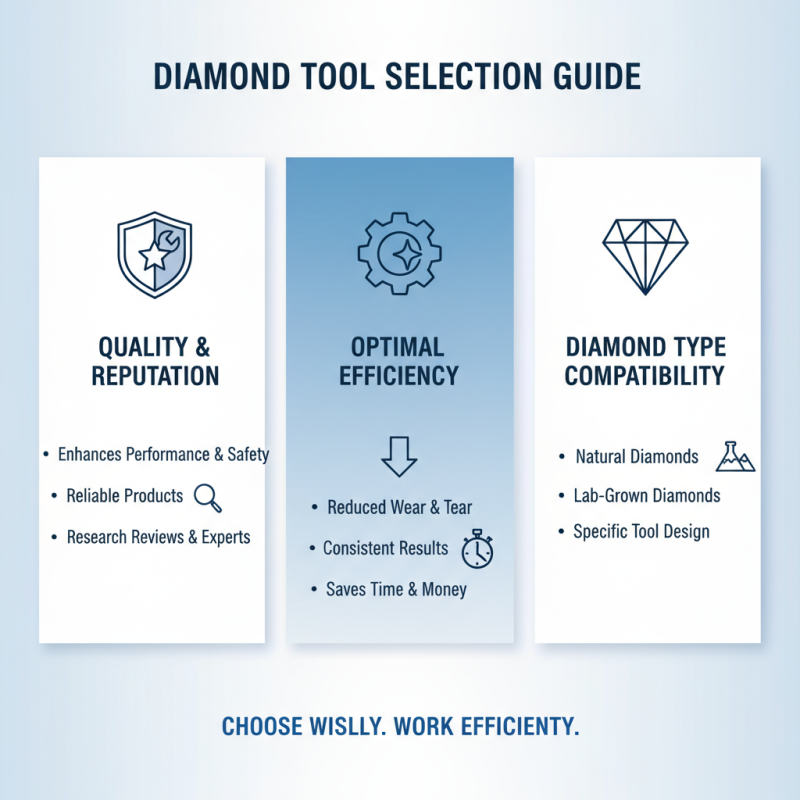

Assessing Quality and Brand Reputation in Diamond Tools

When selecting diamond tools for your project needs, assessing the quality and brand reputation is paramount. High-quality diamond tools not only enhance performance but also promote safety and efficiency in your work. Look for reputable brands that have consistently delivered reliable products. Researching customer reviews and expert opinions can reveal insights into a brand's reputation and the durability of their tools. With the rise of lab-grown diamonds, it's important to evaluate whether the tools you choose are designed specifically for the type of diamond you are working with, ensuring optimal results.

Additionally, the feedback from online platforms can significantly impact brand perception. A brand with positive reviews on various platforms typically reflects the satisfaction of its customers and their trust in the product's quality. Ensuring that the tools you select come from well-reviewed brands can mitigate risks and set a solid foundation for your project's success. Always consider the experiences of others alongside product specifications to make informed choices when investing in diamond tools.

Maintenance Tips for Prolonging the Life of Diamond Tools

Proper maintenance is essential for prolonging the lifespan of diamond tools, ensuring that they remain effective and efficient for various projects. One key aspect of maintenance is regular cleaning. After use, diamond tools should be free of debris and residue that can affect their performance. A simple wash with water or a soft brush can prevent build-up that leads to premature wear. Additionally, avoiding exposure to harsh chemicals will help preserve the integrity of the diamond surface.

Another important maintenance tip is to use diamond tools within their recommended parameters. Each tool has specific settings regarding speed and pressure; adhering to these guidelines minimizes the risk of overheating and damage. Furthermore, storing diamond tools in a dry and safe environment, away from unnecessary contact with other materials, can prevent chipping and breakage. Finally, periodically inspecting tools for signs of wear and tear allows for early detection of potential issues, enabling timely repairs or replacements that can save money and enhance performance in the long run.

Related Posts

-

Innovative Solutions for Enhanced Performance in Diamond Tools Industry

-

How to Choose the Right Diamond Tools for Optimal Cutting Efficiency Based on Industry Standards

-

Top Strategies for Sourcing the Best Diamond Grinding Tools Globally: Insights and Data

-

Top Strategies for Maximizing Efficiency with Best Concrete Grinding Machines

-

How to Choose the Right Concrete Grinding Equipment for Your Project Needs

-

Unlocking the Secrets of Diamond Grinding Techniques and Their Impact on Tool Longevity