Office USA: 706-658-1122 | Tech Support: 706-362-4813

Office Bulgaria: +359 431 64477

Ultimate Guide to Choosing the Best Fabrication Tools for Your Projects

In the ever-evolving world of manufacturing and construction, the selection of the right fabrication tools is crucial for achieving efficiency, precision, and quality in projects. According to a recent report by the National Institute of Standards and Technology (NIST), the use of advanced fabrication tools can enhance productivity by up to 30%, illustrating the significant impact these tools have on operational success. As industries increasingly embrace automation and smart technologies, understanding the diverse types of fabrication tools available is essential for professionals looking to optimize their workflows. This guide will compare various fabrication tools, highlighting their characteristics, advantages, and application scenarios, ultimately assisting you in making informed choices that align with your project requirements.

Key Trends in Fabrication Tools for 2025: What to Expect

As we approach 2025, the landscape of fabrication tools is evolving rapidly, influenced by key trends across various manufacturing sectors. The semiconductor manufacturing equipment market is set to reach an estimated revenue of $109.24 billion in 2024, highlighting the growing demand for advanced fabrication technologies. This surge indicates that companies are increasingly investing in tools that support the fascinating transitions within the semiconductor industry, which is crucial for the production of faster and more efficient devices.

In addition, the life sciences sector is witnessing a pivotal shift towards digital transformation. Many manufacturers in the medical device industry anticipate a heavier reliance on analytics and automated reporting by 2025. This infrastructure will not only enhance production efficiency but will also improve compliance and quality assurance, critical factors in the highly regulated medical landscape. Concurrently, the push for smart manufacturing is expected to significantly boost agility and productivity, illustrating the industry's dedication to leveraging technology for improved operational outcomes.

These trends suggest that as we move forward, the selection of fabrication tools will need to reflect a balance of innovation, compliance, and efficiency to meet the complex demands of future projects.

Emerging Technologies Revolutionizing Fabrication Industries

Emerging technologies are significantly transforming the landscape of fabrication industries, offering innovative solutions that improve efficiency, accuracy, and cost-effectiveness. According to a report by Market Research Future, the global fabrication technology market is projected to reach $38 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%. This growth is driven by advancements in automation, additive manufacturing, and digital fabrication techniques that enable more intricate designs while minimizing waste.

As you choose the best fabrication tools for your projects, consider incorporating 3D printing technology. This method not only allows for rapid prototyping but also enables the production of complex geometries that traditional methods struggle to achieve. A study by Wohlers Associates indicates that the 3D printing market is expected to surpass $40 billion by 2024, making it a vital component of any modern fabrication toolkit.

Another technology to watch is the integration of IoT and AI in fabrication tools. These technologies facilitate smart manufacturing, where machines communicate and optimize production processes in real-time. According to McKinsey, productivity in the manufacturing sector could increase by 20-30% through these advanced technologies. To maximize your fabrication efficiency, ensure your tools are compatible with IoT systems, allowing for seamless data flow and enhanced operational control.

Sustainable Materials: The Future of Fabrication Tool Choices

In the realm of fabrication, sustainability is no longer a mere buzzword; it's a crucial consideration for tool selection and project execution. As we become increasingly aware of our environmental footprint, the demand for sustainable materials in fabrication tools has surged. From recycled metals to bio-based composites, these innovative materials not only reduce waste but also enhance the durability and functionality of tools. By choosing sustainable options, fabricators can contribute to a circular economy, where resources are repurposed and longevity is valued over disposability.

Moreover, the evolution of fabrication tools has paved the way for smarter choices. Many manufacturers are now embracing eco-friendly practices in their production processes, ensuring that their tools are not just powerful but also environmentally responsible. Implementing tools made from sustainable materials can lead to significant energy savings during both production and use. As fabricators prioritize these options, they are not just investing in quality tools but also in a future where fabrication aligns with ecological stewardship, fostering a healthier planet for generations to come.

Maximizing Efficiency: Top Fabrication Tools to Invest in 2025

Choosing the right fabrication tools can significantly impact the efficiency and quality of your projects. As we look ahead to 2025, investing in advanced tools will not only enhance your productivity but also ensure precision in your work. Whether you're a professional contractor or a dedicated DIY enthusiast, arming yourself with the right tools makes all the difference.

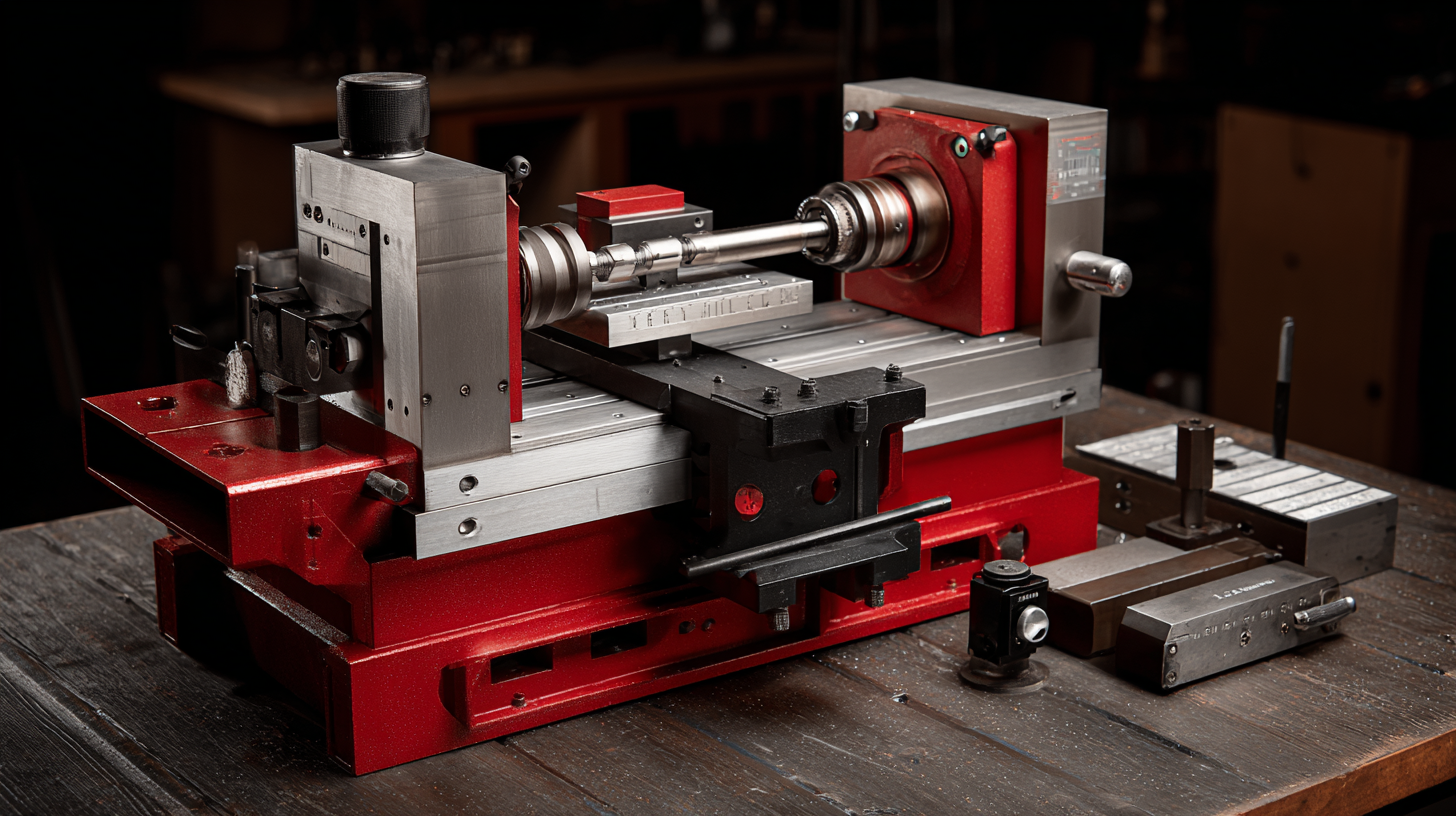

One of the top tools to invest in is a high-quality CNC machine. These machines offer unparalleled precision and can handle complex designs with ease. When selecting a CNC, consider options that come with user-friendly software, allowing you to streamline your workflow.

Another essential tool to consider is a laser cutter. These devices are perfect for cutting a wide array of materials with minimal waste and maximum accuracy. It’s beneficial to look for a laser cutter that features adjustable power settings, enabling you to customize for different materials.

Tip: Always assess the scalability of your tools. Investing in equipment that can grow with your aspirations will save you money and time in the long run. Another tip is to prioritize quality over price – high-end tools often come with better support and durability, making them worthwhile investments.

Top Fabrication Tools to Invest in 2025

Essential Skills for Using Advanced Fabrication Tools Effectively

When embarking on a fabrication project, mastering the essential skills for using advanced fabrication tools is crucial for achieving high-quality results. According to a report by the Fabricators & Manufacturers Association, nearly 70% of skilled workers in the fabrication industry believe that ongoing training is vital in adapting to new technologies and tools. This highlights the significance of investing time in skill development to effectively maneuver complex machinery, such as CNC machines and laser cutters, which have revolutionized the fabrication process.

Proficiency in these advanced tools not only enhances accuracy and efficiency but also contributes to the overall productivity of projects. The Manufacturing Institute's Skills Gap report indicates that 2.4 million jobs could go unfilled in the manufacturing sector by 2028 if workforce skills do not align with technological advancements. Thus, acquiring expertise in programming, operating, and maintaining these tools is imperative. Engaging in workshops, certifications, and hands-on experience can significantly bolster a fabricator's ability to leverage these tools, leading to innovative outcomes and improved project timelines.