Office USA: 706-658-1122 | Tech Support: 706-362-4813

Office Bulgaria: +359 431 64477

How to Choose the Right Concrete Power Trowel for Your Project

Choosing the right concrete power trowel for your project is crucial for achieving a smooth and durable finish. Michael Johnson, a leading expert in concrete equipment, emphasizes the importance of selecting the appropriate tools for specific job requirements, stating, “The right concrete power trowel can make the difference between a flawless surface and extensive rework.” Whether you are a seasoned contractor or a DIY enthusiast, understanding the various types of power trowels available and their specific features can significantly impact the outcome of your project.

Concrete power trowels are essential for leveling and finishing concrete surfaces, but with a plethora of options on the market, making an informed decision is vital. In this guide, we will explore key factors to consider when choosing a concrete power trowel, including the size of the project, the type of concrete being used, and the specific finish desired. By understanding these elements, you can confidently select a power trowel that not only meets your needs but also enhances your overall project efficiency and effectiveness.

Understanding the Types of Concrete Power Trowels Available

When it comes to concrete finishing, choosing the right power trowel is crucial for achieving a smooth and durable surface. Power trowels are broadly categorized into two main types: walk-behind and ride-on trowels. Walk-behind trowels are ideal for smaller jobs or areas where maneuverability is key. They typically come equipped with rotating blades that can be adjusted for varying levels of finish, making them versatile for different project requirements. According to industry reports, walk-behind trowels account for approximately 60% of the market due to their efficiency and ease of use for smaller concrete pouring tasks.

On the other hand, ride-on trowels are designed for larger projects, where speed and productivity are paramount. These machines can cover vast areas in a shorter time frame, thanks to their powerful engines and larger pan sizes. A report from the American Concrete Institute suggests that using ride-on trowels can improve finishing efficiency by up to 40% compared to walk-behind models, especially on big slabs. Each type of trowel has its unique strengths, and understanding their specifications, like blade size and power output, can help contractors choose the right tool for their specific concrete finishing tasks.

Identifying Key Project Requirements for Trowel Selection

When selecting the right concrete power trowel for a project, it is essential to first identify the key requirements that will dictate the type of equipment needed. The size of the area to be finished plays a significant role; for larger projects, a ride-on trowel may be more efficient, while smaller jobs can often be handled with a walk-behind model. According to industry reports, job efficiency can improve by up to 20% when the appropriate trowel size is utilized, allowing for faster completion times and reduced labor costs.

Additionally, the finish specifications of the concrete surface must be considered. Projects that require a high-gloss finish might necessitate the use of trowels with specific blade types and adjustments for finer control. Research indicates that the trowel's weight and rotational speed can impact the quality of the finish as well; heavier trowels tend to produce a smoother surface, while variable speed options allow operators to tailor their work to the conditions of the mix and environmental factors. Therefore, understanding the necessary finish specifications is crucial in the decision-making process to ensure not only the right appearance but also the durability of the finished concrete.

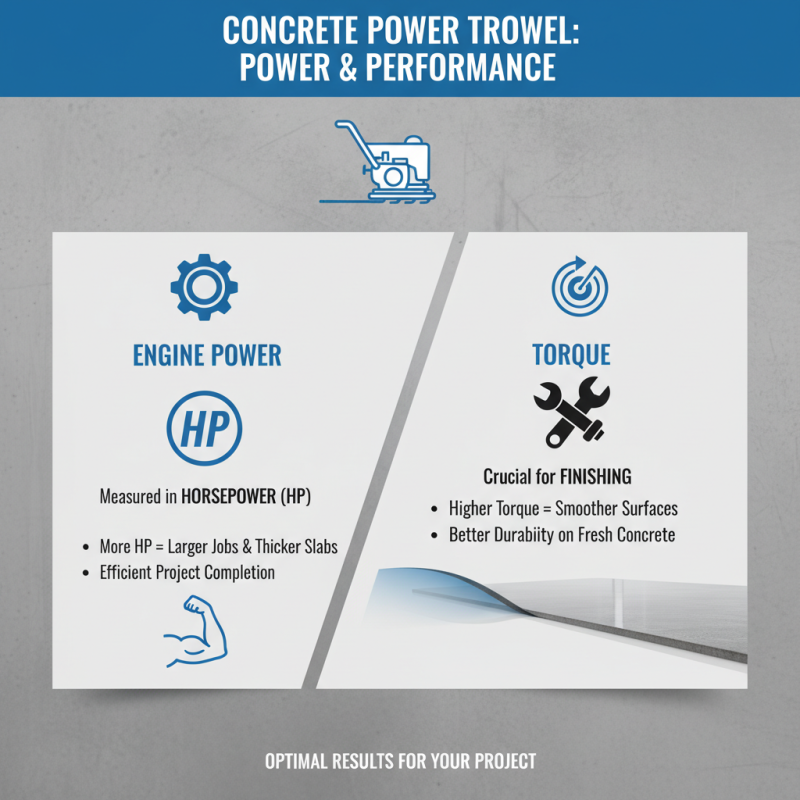

Evaluating Power and Performance Features of Trowels

When selecting a concrete power trowel for your project, understanding the power and performance features is crucial for achieving optimal results. One of the key factors to consider is the engine power, typically measured in horsepower. A more powerful engine can handle larger jobs and thicker slabs, ensuring that you can complete your project efficiently. Additionally, trowels with higher torque are better at finishing freshly poured concrete, enabling smoother surfaces and better durability.

Another important performance feature to evaluate is the weight of the trowel. Heavier trowels tend to provide better float action, allowing them to flatten and finish concrete surfaces more effectively. Conversely, lighter trowels can be easier to maneuver, making them suitable for smaller or intricate projects. Furthermore, look for adjustable pitch options that allow you to change the angle of the blades, as this flexibility can enhance performance on varying surface textures. Ultimately, analyzing these power and performance features will guide you in choosing the right trowel to fit the specific demands of your concrete project.

Considering Blade Options and Finishing Techniques

When selecting the right concrete power trowel for your project, the choice of blades can significantly influence the finishing quality of the surface. Trowel blades come in a variety of designs tailored for specific finishing techniques. For instance, standard blades are ideal for initial floating and leveling, providing a smooth base. Conversely, high-precision blades are designed for polished finishes, ensuring a fine sheen that enhances aesthetic appeal. Depending on the desired surface texture and durability, you might also consider using combination blades, which offer versatility for different phases of your project.

In addition to blade options, the finishing techniques employed during troweling play a crucial role in the final outcome. Techniques such as wet finishing are often favored for a high-gloss surface but require careful timing to prevent imperfections. On the other hand, dry finishing can produce a more resilient texture, suitable for outdoor applications or heavy traffic areas. Understanding these options allows you to choose the most appropriate power trowel that aligns with both your project needs and desired finish quality, ensuring a successful concrete installation.

Assessing Budget and Maintenance Needs for Your Trowel Choice

When selecting the right concrete power trowel for your project, it’s essential to assess both your budget and the long-term maintenance needs associated with your choice. Power trowels vary significantly in price, depending on their features and capabilities. While it may be tempting to opt for the cheapest model, consider the potential costs incurred through higher maintenance or replacement frequency. Investing in a more durable, efficient model can save you money in the long run and enhance the quality of your finished work.

Tips: Always review the warranty and support options available for a trowel. A solid warranty can provide peace of mind, especially if you’re choosing a more expensive model. Additionally, consider the availability of replacement parts in case repairs are needed, as this can significantly affect downtime during your project.

Regular maintenance is crucial in ensuring the longevity of your power trowel. Make it a practice to clean the trowel after each use and inspect the blades regularly for wear and tear. Understanding how to maintain your equipment can prevent costly breakdowns and ensure your trowel remains in good working order throughout your project. Prioritize models that are easier to service, as this can simplify your maintenance routine and keep your workflow uninterrupted.

Related Posts

-

What is a Concrete Power Trowel and How Does it Work

-

Exploring the Future: How Concrete Machines Are Revolutionizing Construction Efficiency

-

Top Concrete Finishing Tools for a Perfect Surface in 2025

-

Solutions for Achieving Perfect Finishes with the Best Polisher Machine

-

What is Concrete Grinding and How Does it Transform Surfaces?

-

Top 10 Hand Grinders to Elevate Your Coffee Experience in 2025