Office USA: 706-658-1122 | Tech Support: 706-362-4813

Office Bulgaria: +359 431 64477

Top Concrete Grinding Equipment for 2026 What Should You Know?

As we approach 2026, the concrete grinding equipment industry is on the verge of revolutionary changes. John Smith, an esteemed expert in the field, states, “The right equipment can transform any concrete surface.” His insight illuminates the importance of selecting appropriate tools for grinding projects.

Concrete grinding equipment is essential for achieving smooth finishes and removing imperfections. This equipment varies from hand-held grinders to large, industrial machines. Each type serves different needs, impacting efficiency and results.

As new technologies emerge, understanding these advancements becomes crucial. It’s easy to focus solely on equipment capabilities. However, awareness of user experience and ongoing maintenance is key. Machinery that works well today might not meet future demands. Continuous evaluation is necessary to stay ahead in this competitive landscape.

Top Trends in Concrete Grinding Equipment for 2026

As we look toward 2026, concrete grinding equipment is evolving rapidly. New technology is making these tools more efficient. Operators now demand quieter machines. Equipment that minimizes dust is also high on the list. Environmental concerns are pressing, and advancements in filtration systems are addressing these issues.

Tips for choosing equipment: Look for machines with adjustable RPM. This can enhance precision based on project requirements. Weight should also be considered. Heavier grinders tend to perform better on tough surfaces. However, mobility can suffer.

Another trend is the rise of automation. Operators can program machines for consistency. This reduces human error and improves results. However, reliance on automated systems may lead to skill degradation. Balance is essential in the workforce.

Consider electric models over gas-powered ones. They are generally quieter and cleaner. Understanding the requirements of each project is crucial. Options vary based on surface type and finish desired. Keeping up with trends will optimize your operations.

Top Concrete Grinding Equipment for 2026

| Equipment Type | Power Source | Weight (lbs) | Grinding Speed (RPM) | Price Range ($) |

|---|---|---|---|---|

| Handheld Grinder | Electric | 12 | 8000 | 150 - 300 |

| Floor Grinder | Electric | 150 | 3000 | 2000 - 3500 |

| Diamond Grinder | Gas | 200 | 1500 | 3000 - 5000 |

| Polisher | Electric | 100 | 2000 | 1000 - 2000 |

| Concrete Scarifier | Gas | 250 | 1200 | 4000 - 7000 |

Essential Features to Look for in Concrete Grinders

When choosing concrete grinders, certain essential features stand out. One vital aspect to consider is the power of the motor. A more powerful motor can handle tough surfaces and offer a smoother finish. Do not underestimate the importance of weight as well. A heavier grinder often offers better stability during use, which can help achieve consistent results.

Another critical feature is the type of grinding wheels used. Diamond grinding wheels are preferred for their durability and effectiveness. They cut through tough materials with relative ease. Look for adjustable speeds, too. This feature allows users to adapt to different surfaces and job requirements. Having control over the speed can prevent damage to softer materials.

Dust collection systems are also pivotal. A good grinder should minimize dust production. This keeps the work area clean and safer for operators. Yet, not all systems are effective. Some require frequent upkeep, which may hinder workflow. It's essential to weigh these details carefully. Consider what suits your specific needs when choosing. Regularly reviewing performance and adjusting settings is key to achieving great results.

Top Concrete Grinding Equipment for 2026

This chart illustrates the essential features to consider when selecting concrete grinders for 2026, including motor power, weight, and grinding width. Each feature plays a crucial role in determining the efficiency and effectiveness of the grinding process.

Types of Concrete Grinding Machines: A Comprehensive Overview

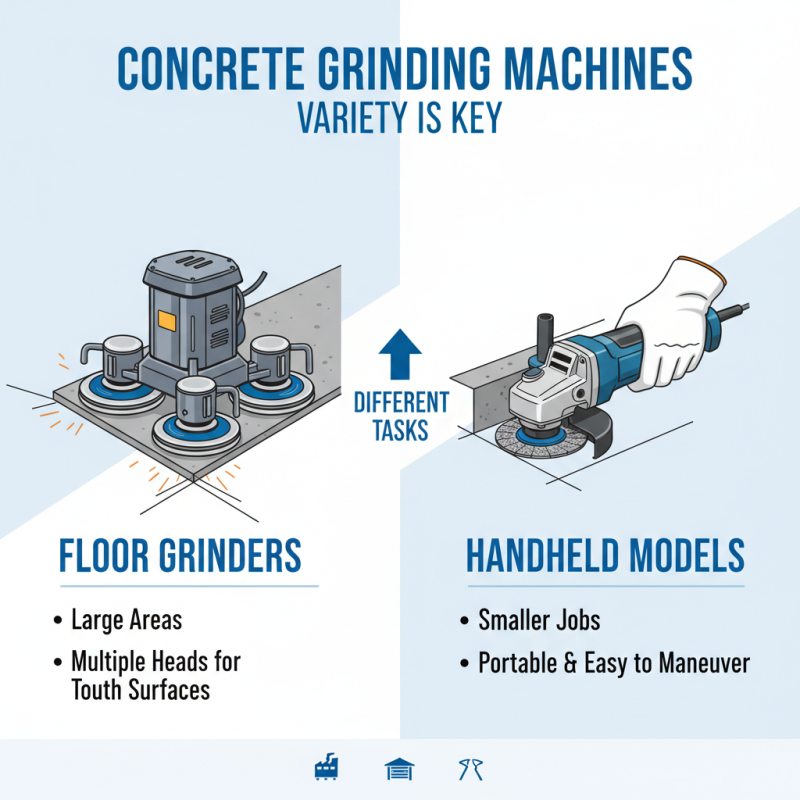

When it comes to concrete grinding machines, variety is key. There are several types available, each suited for different tasks. Floor grinders are common and effective for large areas. These machines often have multiple heads that can handle tough surfaces. Handheld models can tackle smaller jobs. They are portable and easy to maneuver.

Another type is the planetary grinder. It works by using rotating heads to achieve a smooth finish. These machines are ideal for surfaces that require precision and detail. For more intensive tasks, heavy-duty grinders are used. They can handle thick coatings and uneven surfaces. It’s important to choose the right type of machine for your specific needs.

Each type has its pros and cons. The wrong choice can lead to poor results. Some users may find handheld models awkward over larger spaces. Equipment maintenance is also crucial. Neglect can result in diminished performance. Always assess your project requirements before selecting an appropriate grinding machine. This careful consideration will ensure better outcomes in your concrete grinding tasks.

Safety Considerations When Using Concrete Grinding Tools

When using concrete grinding tools, safety is crucial. Workers often overlook protective gear. Always wear safety goggles to shield your eyes from dust and debris. Ear protection is also vital. The noise from grinding equipment can cause long-term hearing damage.

Don't forget about respiratory health. Concrete dust can be harmful. Using a dust extraction system helps minimize inhalation of harmful particles. Moreover, good ventilation in the workspace is essential. It reduces the risk of respiratory issues.

Tips: Regularly inspect your grinding equipment. Check for any wear and tear. Damaged tools can be hazardous. Remember, a clean workspace is safer. Concrete dust and debris can create slipping hazards. Keeping your area organized will help prevent accidents. Safe practices lead to a productive environment.

Future Innovations in Concrete Grinding Technology and Techniques

As we progress toward 2026, innovations in concrete grinding technology are shaping the industry. Emerging tools aim for efficiency, safety, and sustainability. According to a recent industry report, the concrete surface preparation market is projected to grow significantly, with advancements in diamond grinding and polishing equipment leading the way. Improved designs allow for faster grinding with less material waste, contributing to eco-friendliness.

Electric-powered grinders are gaining popularity. They reduce noise and emissions compared to gas models. This trend aligns with global pushes for greener construction practices. In contrast, some traditional grinders still pose challenges, like higher dust emissions. Advances in dust collection systems are essential. They help ensure a cleaner working environment and comply with stricter regulations.

Tip: Always assess the workspace before selecting equipment. The right machine can drastically improve productivity and safety.

Another important trend is the integration of technology. Smart sensors are now being incorporated in grinding machines. They monitor performance and adjust settings automatically. However, reliance on technology can lead to over-dependence. Not every job site is the same, and flexibility remains crucial.

Tip: Regular training is vital. Equip your team to understand both new and old techniques. Adaptability is key in this evolving landscape.

Related Posts

-

Understanding the Challenges in Achieving the Best Concrete Grinding Equipment Standards

-

Top Strategies for Sourcing the Best Diamond Grinding Tools Globally: Insights and Data

-

Top Strategies for Maximizing Efficiency with Best Concrete Grinding Machines

-

Innovative Solutions for Enhanced Performance in Diamond Tools Industry

-

How to Choose the Right Diamond Tools for Optimal Cutting Efficiency Based on Industry Standards

-

How to Choose the Right Concrete Grinding Equipment for Your Project Needs