Office USA: 706-658-1122 | Tech Support: 706-362-4813

Office Bulgaria: +359 431 64477

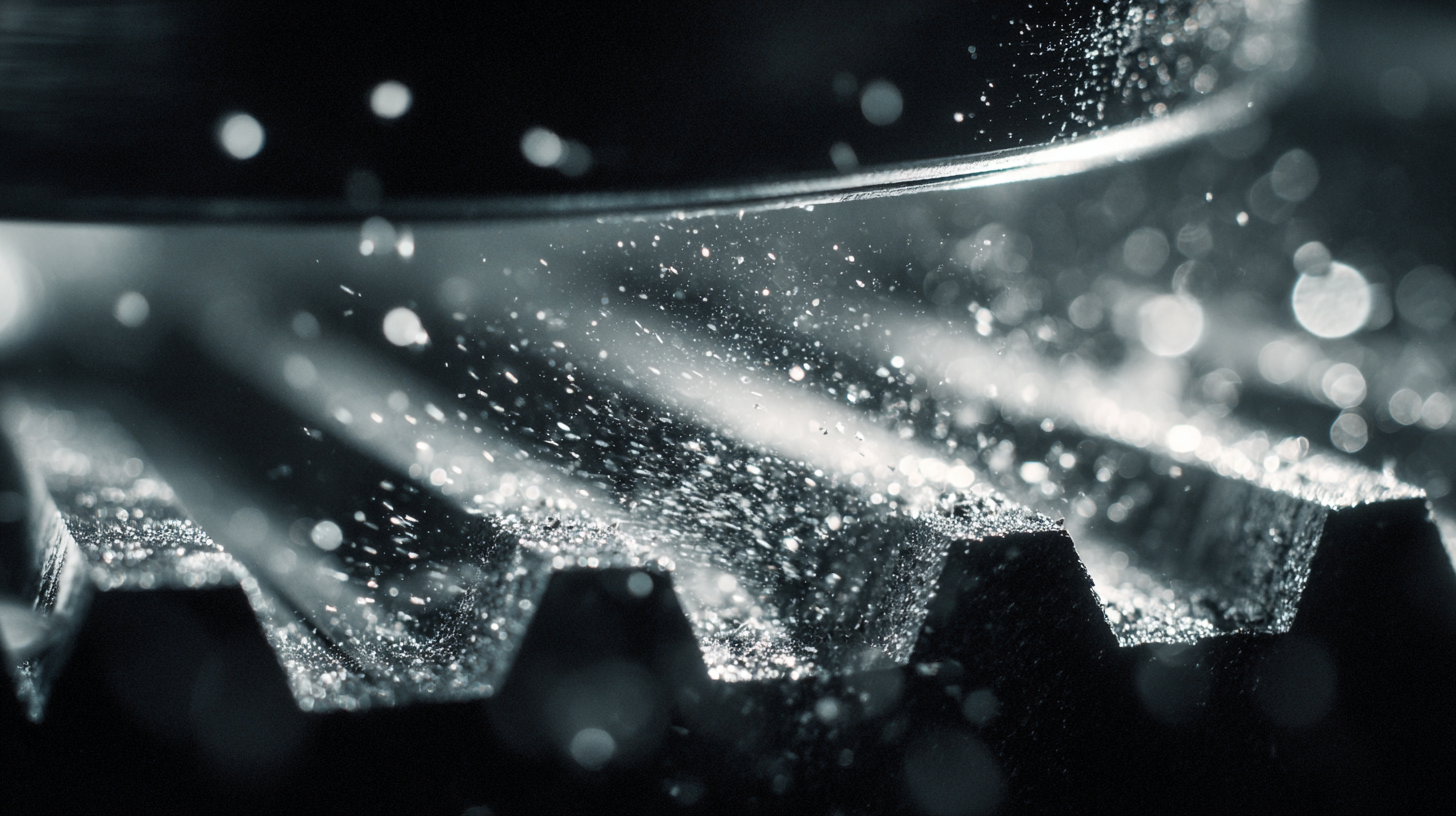

Innovative Solutions for Enhanced Performance in Diamond Tools Industry

In the competitive landscape of the diamond tools industry, the relentless pursuit of performance enhancement drives innovation at every turn. As businesses seek to refine their manufacturing processes and improve overall efficiency, understanding the various types of diamond tools becomes crucial. This blog delves into the remarkable advancements and inventive solutions that are shaping the future of diamond tool applications. From saw blades to grinding wheels, the diversity of diamond tool types plays a pivotal role in meeting the ever-evolving demands of various sectors, including construction, manufacturing, and automotive. By exploring these innovative developments, we aim to shed light on how they contribute not only to superior performance but also to sustainability and cost-effectiveness in the diamond tools industry. Join us as we uncover the transformative impact of innovation in enhancing the capabilities and effectiveness of diamond tools.

Emerging Technologies Revolutionizing Diamond Tool Manufacturing Processes

The diamond tools industry is undergoing a significant transformation, fueled by emerging technologies that are redefining manufacturing processes. Innovations such as additive manufacturing and advanced bonding techniques are poised to enhance the performance and durability of diamond tools. According to a recent report by MarketsandMarkets, the global diamond tools market is projected to grow from $5 billion in 2021 to over $7 billion by 2026, underscoring the increasing demand for high-performance tools in various industries, including construction and automotive.

One of the most impactful technologies is the integration of AI and machine learning in the production process. These smart technologies can optimize the design and manufacturing parameters, resulting in improved tool efficiency and reduced wear. Furthermore, advancements in nanotechnology are allowing for the creation of ultra-thin diamond coatings that enhance cutting precision and extend tool life. A study published in the Journal of Manufacturing Processes highlights that tools produced with these innovative methods can demonstrate up to 30% higher performance compared to traditional manufacturing techniques, illustrating the potential for substantial improvements in both productivity and cost-effectiveness within the industry.

Sustainable Materials and Eco-Friendly Practices in Diamond Tools Production

In the diamond tools industry, the shift towards sustainable materials and eco-friendly practices is becoming increasingly vital. As consumers demand greener products, manufacturers are challenged to innovate while minimizing their environmental footprint. By utilizing recycled diamond materials and exploring biodegradable binding agents, companies can produce high-performance tools that are less harmful to the planet. This not only attracts eco-conscious consumers but also aligns with global sustainability goals.

Tips for achieving sustainability in diamond tool production include investing in advanced recycling technologies that reclaim diamond waste, thus enhancing resource efficiency. Additionally, consider implementing a life cycle assessment (LCA) to evaluate the environmental impacts of various materials throughout their production, use, and disposal phases. This comprehensive approach empowers manufacturers to make informed decisions that benefit both the environment and their bottom line.

Moreover, collaboration with suppliers committed to sustainable practices can significantly enhance eco-friendliness in the supply chain. Engage in partnerships that prioritize responsible sourcing and share expertise on green manufacturing processes. By integrating these eco-friendly practices, the diamond tools industry can lead the way in sustainable innovation, paving the path for future advancements.

Case Studies: Successful Implementations of Innovative Diamond Tool Solutions

In the rapidly evolving diamond tools industry, several companies have successfully implemented innovative solutions that significantly enhance performance. One notable case is a leading manufacturer that integrated advanced coatings on their diamond blades. This innovation not only improved the wear resistance of the tools but also reduced friction during cutting operations. As a result, they experienced a 30% increase in tool life and a remarkable reduction in downtime, affirming the value of adopting cutting-edge technologies in product development.

Another compelling example can be found in a company specializing in diamond grinding wheels. By incorporating smart technology into their manufacturing process, they were able to monitor real-time wear and adjust the grinding parameters accordingly. This proactive approach led to consistent surface finishes and increased efficiency in the grinding process. Customers reported a 25% increase in productivity, showcasing how leveraging innovative methodologies can dramatically transform operational metrics and customer satisfaction within the diamond tools sector.

Enhancing Tool Longevity: Breakthroughs in Wear-Resistant Coatings

The diamond tools industry has made significant strides in enhancing tool longevity through innovative wear-resistant coatings. These breakthroughs are essential for improving the efficiency and performance of diamond tools, which are widely used in various applications ranging from construction to precision machining. The introduction of advanced materials, such as nanostructured coatings and multi-layered films, has proven effective in minimizing wear and tear during rigorous use, thus extending the lifespan of these tools.

Incorporating these wear-resistant coatings not only reduces the frequency of tool replacements but also lowers overall operational costs for manufacturers. Furthermore, these innovations contribute to a more sustainable approach in the industry by decreasing waste and resource consumption. As the demand for high-performance tools continues to grow, the ongoing development of cutting-edge coatings will play a pivotal role in ensuring that diamond tools meet the ever-increasing standards of durability and efficiency. This evolution reinforces the importance of research and development efforts aimed at enhancing the material properties that define the future of the diamond tools industry.

Innovative Solutions for Enhanced Performance in Diamond Tools Industry

This chart illustrates the effectiveness of various wear-resistant coatings on the longevity of diamond tools. The data showcases the average lifespan improvement (in hours) of diamond tools with different coating technologies.

Integrating Smart Technologies for Real-Time Performance Monitoring in Diamond Tools

In the diamond tools industry, the integration of smart technologies has revolutionized the approach to performance monitoring. Real-time data collection and analysis allow manufacturers to track the efficiency and effectiveness of diamond tools throughout their lifecycle. By utilizing sensors and IoT (Internet of Things) devices, companies can gather critical information such as temperature, vibration, and wear rates, enabling timely interventions and proactive maintenance strategies. This shift from traditional monitoring methods to dynamic, data-driven solutions facilitates better decision-making and optimizes operational workflows.

The implementation of these smart technologies not only enhances productivity but also reduces downtime and operational costs. With advanced analytics, manufacturers can predict tool failure before it occurs, ensuring that production schedules remain uninterrupted. Furthermore, real-time performance insights foster continuous improvement, as manufacturers can adjust their processes based on live feedback. Embracing these innovative solutions not only places companies at the forefront of the diamond tools industry but also underscores their commitment to quality and efficiency in an increasingly competitive market.